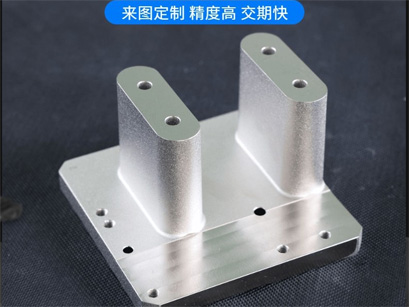

Dongguan Leqi Teng Precision Manufacturing Co., Ltd. engaged in mechanical precision parts processing, large cnc processing, large gantry cnc processing services of large cnc processing center, to provide large gantry computer gong processing, has many years of precision hardware parts processing experience, processing tolerance is small, hardware machinery parts processing manufacturers all know, in addition to tolerance and precision, Surface roughness is also an important index, let's understand the choice of surface roughness of mechanical parts

Dongguan Leqi Teng Precision Manufacturing Co., Ltd. engaged in mechanical precision parts processing, large cnc processing, large gantry cnc processing services of large cnc processing center, to provide large gantry computer gong processing, has many years of precision hardware parts processing experience, processing tolerance is small, hardware machinery parts processing manufacturers all know, in addition to tolerance and precision, Surface roughness is also an important index, let's understand the choice of surface roughness of mechanical parts

The workpiece surface roughness is an important performance index to reflect the workpiece surface topography deviation, it is an important basis to detect the workpiece surface quality, whether the selection is effective or not, directly related to the quality of the product, life and product cost. There are three methods for selecting workpiece surface roughness, namely measurement algorithm, experiment method and simulation method. For the mechanical parts design scheme work, usually by analogy method, this method is simple, fast and reasonable. There should be sufficient reference materials for the application of simulation method. At present, more comprehensive materials and reference materials are given in various mechanical structure design guides. Usually, the surface roughness is suitable for the tolerance class.